Good quality Paper Reel Mill Roll Stand - semi automatic type – Canghai

Good quality Paper Reel Mill Roll Stand - semi automatic type – Canghai Detail:

SPECIFICATION

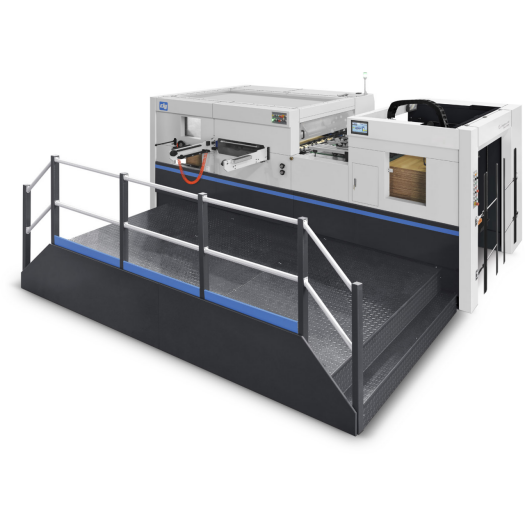

| Machine name: | Automated Manual Die Cutting Machine |

| Specification | MHC-1300B |

| Maximum paper size: | 1300*940mm |

| Minimum paper size: | 470 × 420 mm |

| Maximum die cutting size: | 1280*920mm |

| Max cutting speed: | 5000 sheets/hour |

| Max working pressure: | 300 tons |

| Rated power | 13.5kw |

| Weight : | 18 tons |

| Scope of application | Cardboard ≥250gsm Corrugated paper: 1-7mm |

BRIEF INTRODUCE

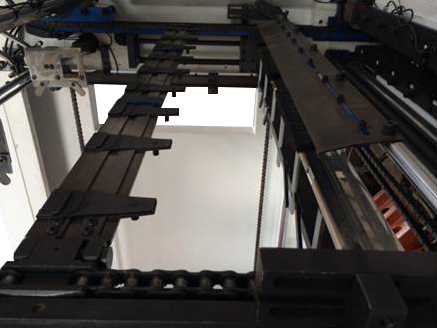

(1)Adopt nodular cast iron-QT500-7, the mainframe wallboard casting by special technology process, thus featuring by high strength, never deformation and ensure the safety of the mainframe wallboard.

(2)Adopt Taiwan-imported intermittent mechanism to ensure that the machine operates accurately and reduce the occurrence of failure rate.

(3)The machine uses NSK imported original bearing.

(4)The machine uses original parts imported from German Moeller, and Japanese OMRON brand, etc.

(5)Key parts of teeth row are imported from Japan.

(6)The craft shaft is adopts Germany Ni-Cr-Mo metal steel, with high precision and will never deforms.

(7)Use the centerline positioning system to realize fast plate changing of worksheet.

(8)Equipped with Dayuan first-developed pressure automatic adjustment device, ensure fast and smooth when they adjusting of die cutting pressure.

(9)Die-cutting plate frame adopts auxiliary plate-installation device, to realize different of model machines can be use universal die-cutting plate.

(10)Equip with touch-screen operation interface in both Chinese and English.

(11)Adopt Japanese SMC pneumatic components to ensure every pneumatic action performs accurately.

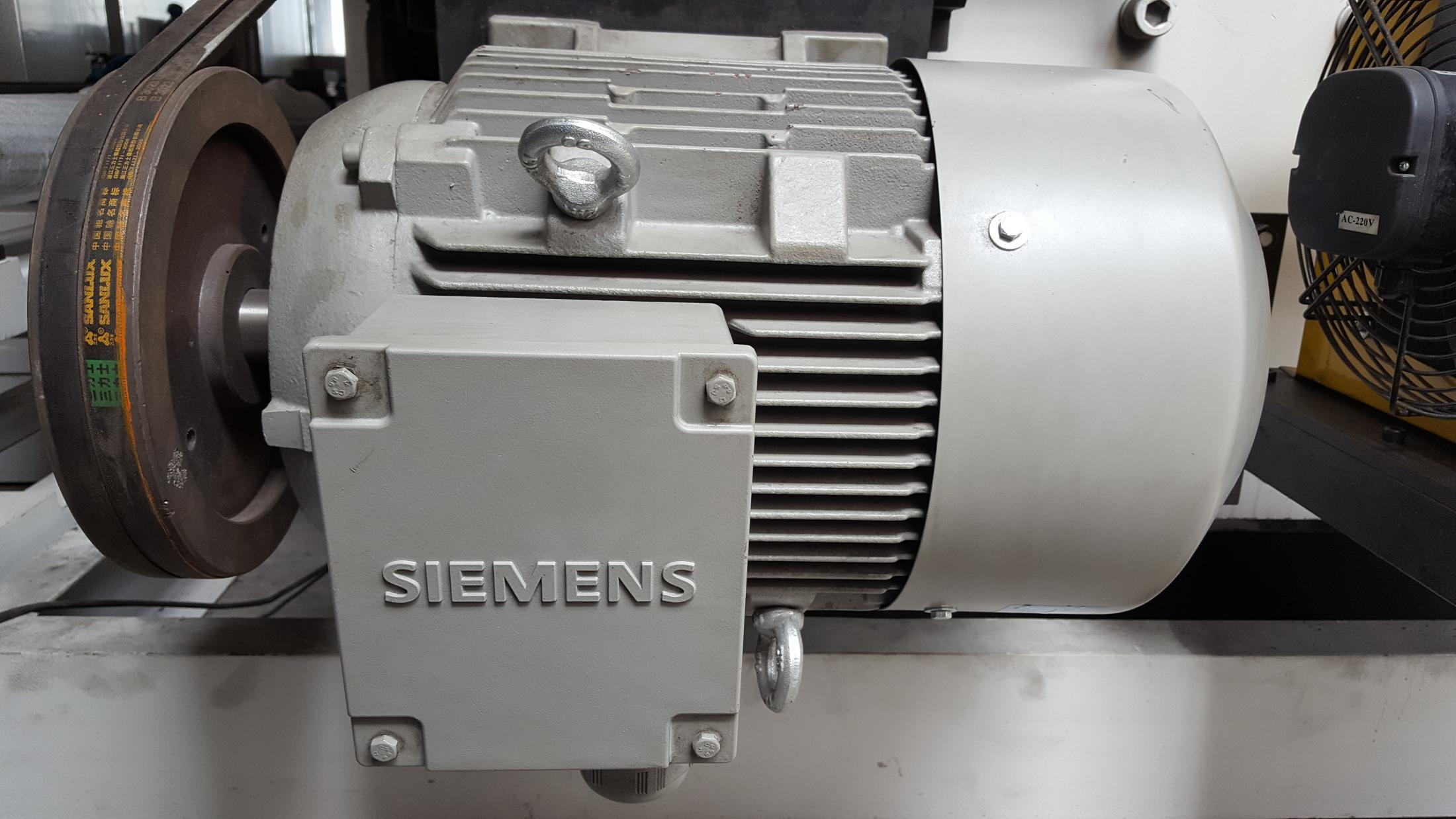

(12)Main motor adopt Germany Siemens brand, to ensures the operation smoothly.

(12)Siemens main motor ensures machine running stable..

PART LIST

|

NO.

|

PART NAME

|

BRAND

|

ORIGIN

|

|

1 |

Main motor

|

SIEMENS

|

GERMANY

|

|

2 |

Button

|

EATON-MOELLER

|

GERMANY

|

|

3 |

Circuit breaker

|

EATON-MOELLER |

GERMANY |

|

4 |

Motor protector

|

EATON-MOELLER |

GERMANY |

|

5 |

AC contactor

|

EATON-MOELLER |

GERMANY |

|

6 |

Air switch

|

EATON-MOELLER

|

GERMANY |

|

7 |

Die pressing base

|

HIGH ALLOY PLATE |

GERMANY |

|

8 |

Crankshaft material

|

Ni-Cr-Mo metal steel

|

GERMANY |

|

9 |

Main drive chains |

IWIS |

GERMANY |

|

10 |

Rotary joint

|

OMPI

|

ITALY

|

|

11 |

Electromagnetic clutch

|

OMPI |

ITALY

|

|

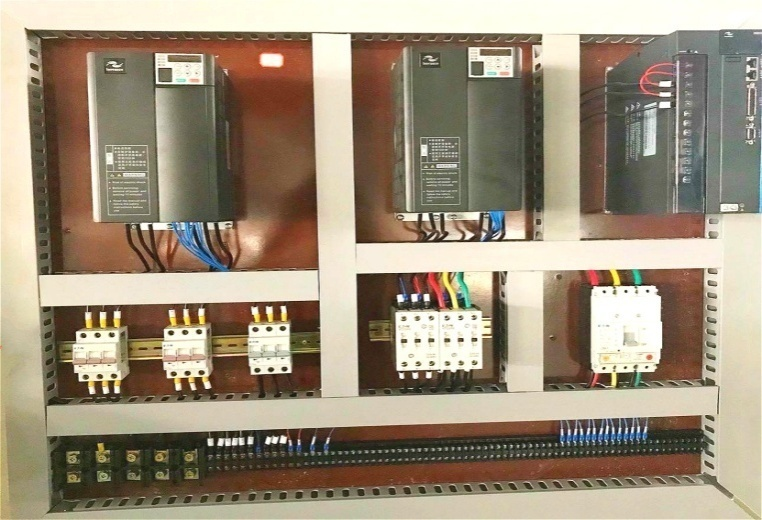

12 |

Frequency converter

|

INOVANCE

|

SHENZHEN

|

|

13 |

Control center

|

INOVANCE

|

SHENZHEN

|

|

14 |

Wallboard and machine body structure

|

Nodular cast iron

|

SHANGHAI

|

|

15 |

Man-machine interface

|

KUNLUN TONG TAI 10.4TFT |

Sino-foreign joint venture

|

|

16 |

Intermediate relay

|

OMRON

|

JAPAN

|

|

17 |

Photoelectric switch

|

OMRON

|

JAPAN

|

|

18 |

Proximity switch

|

OMRON

|

JAPAN

|

|

19 |

Encoder

|

OMRON

|

JAPAN

|

|

20 |

Sensor

|

OMRON

|

JAPAN

|

|

21 |

Fibre

|

OMRON

|

JAPAN

|

|

22 |

Air cylinder

|

AIRTAC

|

TAIWAN

|

|

23 |

Air volume regulator

|

SMC |

JAPAN

|

|

24 |

Main solenoid value

|

AIRTAC

|

TAIWAN

|

|

25 |

Tooth row, tooth slice

|

KUI |

JAPAN |

|

26 |

Counting photoelectric

|

MEIJIDENKI

|

JAPAN

|

|

27 |

Main paper feeding motor

|

SHENGBANG |

TAIWAN

|

|

28 |

Lift motor of paper collecting platform |

SHENGBANG

|

TAIWAN

|

|

29 |

Indexing drives

|

HANDEX

|

TAIWAN

|

|

30 |

Worm and gear

|

WANCENG |

TAIWAN |

Details

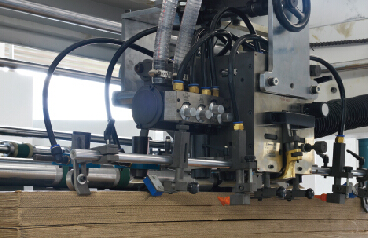

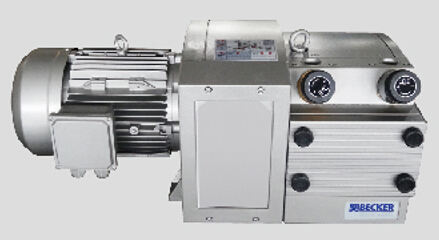

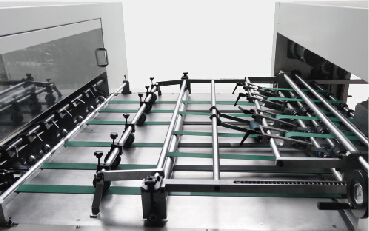

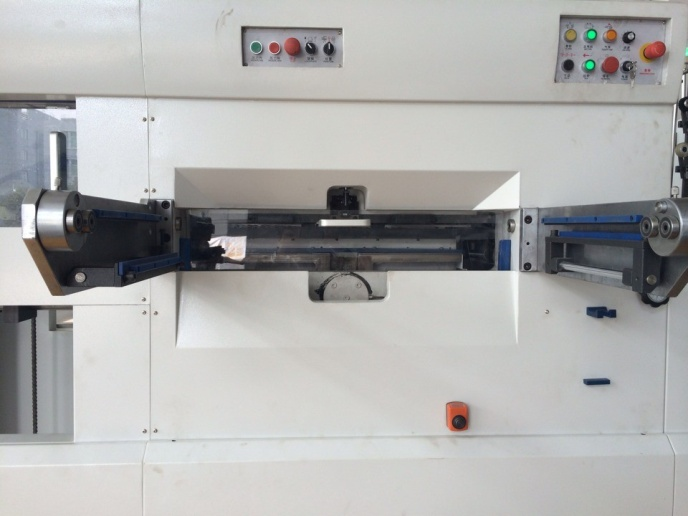

Product detail pictures:

Related Product Guide:

We provide good power in high-quality and progress,merchandising,revenue and internet marketing and operation for Good quality Paper Reel Mill Roll Stand - semi automatic type – Canghai , The product will supply to all over the world, such as: Uzbekistan, Guyana, Sierra Leone, We have got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

A good manufacturers, we have cooperated twice, good quality and good service attitude.