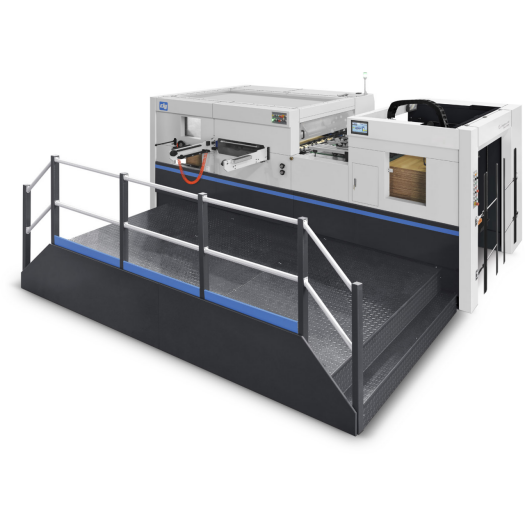

Factory Supply Cardboard Corrugator Line - Sheet Cutter Machine For Corrugated Production Line – Canghai

Factory Supply Cardboard Corrugator Line - Sheet Cutter Machine For Corrugated Production Line – Canghai Detail:

►Structure and Features

1, Cutting length:500mm-9999mm.

2, Cutting precision:±1mm.

3, Uses the independent oil pump and the filter coordinates two groups of copper tubes to distribute in various gears position for the oil,the lubrication and cooling.

4, Helical knife structure,type sawtooth knife,decrease cutting obstruction,low noise.

5, Balance treatment:high quality alloy steel for blade shaft,which helps to keep it good stability.

6, Sun-shape wheels press cardboard in the front and the rear conveyer.The transporting is stable and with even pressure,which avoid jam caused or broken cardboard.

7, This type of Cut-off just consume the one of third energy compare with the common cutter with its especial structure,economize above 70% energy to get more money.

8, Exact and adjustable on gap gear assure knife-edge joggle exactly.running balanceable.

9,Computer system to keep order. Man-machine conversation system NC. automatic adjust cutting speed by cardboard specification and maching.The screen display various production message.Can consult,modification,superaddition and cancel order during running machine.

►Spec

|

Width |

2000mm |

|

Cutting lenth |

500—9999mm |

|

Order keeping |

999orders |

|

Cutting precision |

±1mm |

|

Knive roller diameter |

210mm |

|

Network System |

Computer can link to Auto corr Management system,but the information of existing management system should be provide by user Display: –Present order no. length, sheet quantity –Next order no, length, sheet quantity –Speed, actual length, set length, preset order –Sheet pass quantity, sheet fail quantity |

Product detail pictures:

Related Product Guide:

We aim to find out quality disfigurement from the production and supply the best service to domestic and overseas customers wholeheartedly for Factory Supply Cardboard Corrugator Line - Sheet Cutter Machine For Corrugated Production Line – Canghai , The product will supply to all over the world, such as: Uganda, St. Petersburg, Serbia, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.