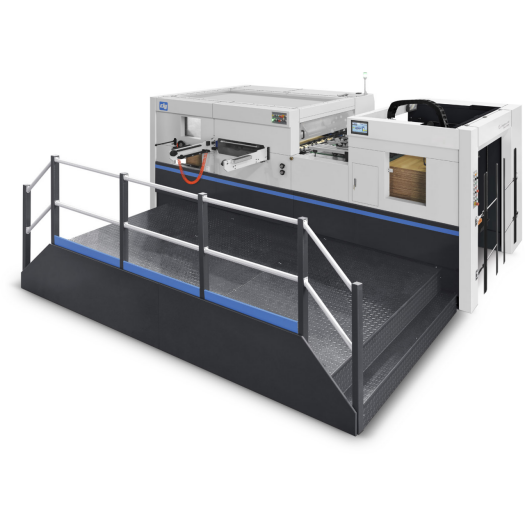

Factory Cheap Hot Automatic Folder Gluer Stitcher Strapper Machine - Semi-auto stitching machine – Canghai

Factory Cheap Hot Automatic Folder Gluer Stitcher Strapper Machine - Semi-auto stitching machine – Canghai Detail:

SPECIFICATION

| Model | QS-2000 | Max.size | 1515*2460mm |

| Speed | 500nail/min | Min.size | 400*606mm |

| Stitching distance | 30-120mm | Motor | 6HP |

| Stitching number | 1-99 nail | Paper feeder height | 900mm |

| Nail species | Single ,double,strong | Machine size | 3000*2300*1800mm |

| Stitch wire | 2.0*(0.65 to 0.75)nn | Machine weight | 2000KGS |

|

Number |

Name |

Brand |

Place of origin |

|

|

Stitching head servo motor |

Mitsubishi |

Japan |

|

02 |

Feeder paper servo motor |

Mitsubishi |

Japan |

|

03 |

PLC、Photoelectric switch, proximity switch |

Omron |

Japan |

|

04 |

Contactor, circuit breaker |

Siemens |

Germany |

|

05 |

Stitching head Reducer |

liming |

Taiwan |

|

06 |

Middle Relay |

Schneider |

France |

|

07 |

Photoelectric, proximity switch |

Schneider |

France |

|

08 |

touch screen |

weilun |

Taiwan |

|

09 |

Breaker |

Schneider |

France |

|

10 |

Bearing |

NSK |

Japan |

|

11 |

Stitching head |

|

Taiwan |

|

12 |

Cylinder, solenoid valve |

Yedeke |

Taiwan |

|

13 |

Gear reducer |

Oute |

Shagnhai |

|

14 |

Worm gear reducer |

zhenyu |

Hanghzou |

|

15 |

Rubber wheel |

|

Taiwan |

SPECIFICATIONBDXJ-2000 high speed semi-automatic nail box machine

1. Mitsubishi double servo drive, accurate accuracy, reduced mechanical transmission parts, can effectively reduce the mechanical failure rate.

2. Weilun touch screen operation, parameters (nail distance, number of nails, nail type, back panel) change quickly and easily

3. The entire control system uses the Japanese Omron PLC control system.

4. The rear electric baffle is driven by a stepping motor, and the size is accurate, and the size is more convenient and quick.

5. The full contactor in the control box is branded by Siemens.

6. Optoelectronic and proximity switches are available in the Omron brand.

7. The bottom mold, the blade is made of Japanese tungsten steel

8. The whole set of nail heads are all made of special steel, and the computer is precision machined.

9. Single nail, double nail and reinforcing nail can be completed in one time, which can meet the different requirements of different customers for nails.

10. Change the size of the carton and adjust the carton nail distance in one minute, which saves time and is easy to operate.

1. The leading edge paper feeding section automatically counts, and the paper feeding table is equipped with a photoelectric sensing device, which automatically rises when feeding.

2. There is automatic counting function in the back section. The number of finished products can be transported separately according to the set number (1-99), which is convenient for packing and bundling.

3. Machine speed: 600 nails / minute.

4. Nail distance: 30-120mm can be adjusted arbitrarily.

5. The paper roller gap is electrically adjusted.

6. Workbench lifting effective height: 900mm

7. Machine size: host 2.8*1.7*1.8 meters

8. Machine weight: 2T

9. Order adjustment of the whole machine, can store 1000 orders.

10. Protection function of the whole machine electrical isolation transformer.

11. Automatic wire feeding system, 20KG flat wire, saving time.

12. Front and rear two-way baffle configuration, can be nailed without cover carton and small cardboard boxes, color boxes.

|

Number |

Name |

Brand |

Place of origin |

|

|

Stitching head servo motor |

Mitsubishi |

Japan |

|

02 |

Feeder paper servo motor |

Mitsubishi |

Japan |

|

03 |

PLC、Photoelectric switch, proximity switch |

Omron |

Japan |

|

04 |

Contactor, circuit breaker |

Siemens |

Germany |

|

05 |

Stitching head Reducer |

liming |

Taiwan |

|

06 |

Middle Relay |

Schneider |

France |

|

07 |

Photoelectric, proximity switch |

Schneider |

France |

|

08 |

touch screen |

weilun |

Taiwan |

|

09 |

Breaker |

Schneider |

France |

|

10 |

Bearing |

NSK |

Japan |

|

11 |

Stitching head |

|

Taiwan |

|

12 |

Cylinder, solenoid valve |

Yedeke |

Taiwan |

|

13 |

Gear reducer |

Oute |

Shagnhai |

|

14 |

Worm gear reducer |

zhenyu |

Hanghzou |

|

15 |

Rubber wheel |

|

Taiwan |

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict high quality regulate, reasonable price tag, excellent support and close co-operation with shoppers, we have been devoted to furnishing the best benefit for our buyers for Factory Cheap Hot Automatic Folder Gluer Stitcher Strapper Machine - Semi-auto stitching machine – Canghai , The product will supply to all over the world, such as: Las Vegas, Georgia, Portland, Due to the stability of our items, timely supply and our sincere service, we are able to sell our merchandise not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We will do our best to serve your company, and establish a successful and friendly cooperation with you.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!