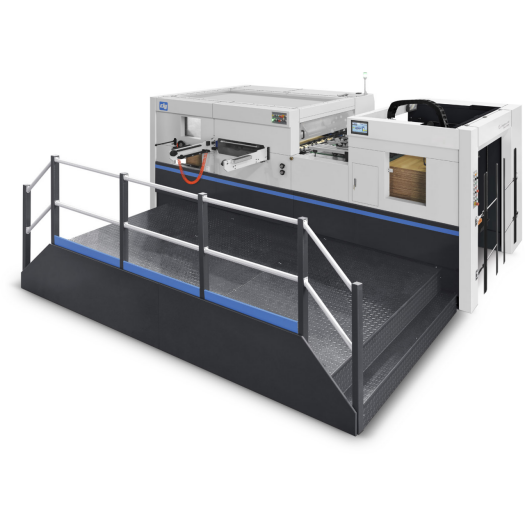

Competitive Price for Creasing And Diecutting Machine - Semi-Automatic Printing Slotting Die Cutting Machine – Canghai

Competitive Price for Creasing And Diecutting Machine - Semi-Automatic Printing Slotting Die Cutting Machine – Canghai Detail:

Machine features

◆ It adopts chain-paper feeding.

◆ transmission gear made from high-hardness heat quality steel which produced according to high precisin requirements and adopt”+” slippery lumps gear transmission device and spray lubrication system.

◆ auto cycing ink-feed system. Ink roller with pneumatic lift and separate rotating,

◆ all the axles of roller must be chrome-plating in order to increase the hardness.

◆ printing , slotting and die cutting electric phase adjusting mechanism adopt planet type gear struture.(it can adjust 360 degree while revolving and stopping.)

◆ electrically separation and pneumatic locking.

◆ module design, any combination of multicolor printing unit.

◆slot unit with manual synchronization adjustment for box height, all knife with electric adjustment,PLC touch screen control,and store orders.

◆ auto count device to show right production volume.

Die-cutter unit

◆ die cut unit roller adopt high quality steel, plated with rigid chrome. High precision dynamic and static balance increase running stable.

◆ mould roller and rubber roller can auto separate by cylinder eccentric device when the machine don’t die cut this can lighten machine load and increase rubber roller and die knife life.

◆ matching with feeding system, it with auto up and down device, the rubber roller will down when feeding paper. The rubber roller will up when stop feeding paper. To make sure every paper die cut correctly.

◆ the mechanical transmission rubber roller move 40mm in left and right side. It also with wear and tear regular could increase the life of rubber roller

◆ die cut phase adopt phase device and electric digital 360 degree adjustment.

◆ machine with rubber amend device, the rubber roller can be used after many times amend.

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can easily guarantee our combined cost competiveness and high-quality advantageous at the same time for Competitive Price for Creasing And Diecutting Machine - Semi-Automatic Printing Slotting Die Cutting Machine – Canghai , The product will supply to all over the world, such as: Mongolia, Honduras, Brasilia, By integrating manufacturing with foreign trade sectors, we can offer total customer solutions by guaranteeing the delivery of right items to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.