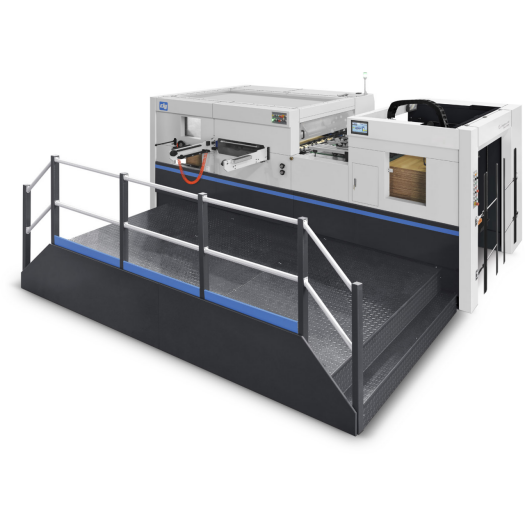

Chinese wholesale Automatic Stitcher Machine - Carton Box Stapler Stitching Machine – Canghai

Chinese wholesale Automatic Stitcher Machine - Carton Box Stapler Stitching Machine – Canghai Detail:

Machine introduction

Our factory is a professional one producing DXJ stitch. The DXJ machine is designed according to the advantaged of the same kind of products produced at

home and abroad. The machine head is structured by double eccentric gears to work together: the pressure angle adopts installation style which is fit for wire cut and which is exchangeable.

All the operation position adopt rolling bearings. Compared to the old machines, the new machines have the following characteristics, such as new appearance, fast speed , steady working, low noise, clinch and long service life. This machine is highly thought of by all the customers after using for a long time. It’s the very equipment that is needed in the cardboard packaging enterprise.

II .Main parameter

Stitching rate: 250times/min

Stitching thickness:2-7 layers

Stitching style: 45°double standing stitches, single standing stitches, single

vertical stitches: 13mm,10mm

Specification of the flat wire:16#,17#,18#,20#

Length 1800mm,1600mm.1400mm,1200mm,900mm,800mm,700mm,600mm 800mm,1600mm.1400mm,1200mm,900mm,800mm,700mm,600mm Electric motor power:0.37KW,0.25KW

Main structure

1.stitchers: the machine is made of HT20-40 which is casted and processed by machine tools and the base, the up right post, the bracket and the beam are connected by bolts to make sure the machine bed is fastened well enough.

2.Staplers: this machine is made of international channel steel and jointed by

advanced engineers. The characteristics are as follows: the whole machine bed is good at enduring wallops and pulls. Moreover , the whole machine bed can never be out of shape, with small volumes, easy to carry, and long service life, it’s small and exquisite and one of the most advanced processing methods.

3.Brackets: the bracket is equipped with alloy mould with double circular area. The position of the circular areas and the dasher are in the same line, the dasher makes the stitch into the cardboard and cooperate with the mould and stitches through the cardboard connecting the box strongly, loosen the four screws, and get your ideal result of the space between the mould and the intersecting knives according to the thickness if the cardboard.

4.Clutch: this clutch works together with the foot board, the chain and the direction button. when the machine head needs to work, step on the foot board and the chain makes the shifting fork move down, then let the clutch and the big belt roller stuck to make the main roller stops running, the motor makes the big belt roller do idle running.

Technical Parameter

| Model | Stapling Speed | Stapling Thickness | Stretching Length of the

holding Arm |

Exterior Dimension | Weight |

| DX-600 | 250 s/min | 3/5 ply | 600 mm | 1100x600x1760 | 300KG |

| DX-900 | 250 s/min | 3/5/7 ply | 900 mm | 1400x600x1760 | 400kg |

| DX-1200 | 250 s/min | 3/5/7 ply | 1200mm | 1700x700x1820 | 600kg |

| DX-1400 | 250 s/min | 3/5/7 ply | 1400mm | 1900x700x1820 | 800kg |

| DX-1800 | 250 s/min | 3/5/7 ply | 1800mm | 2300x700x1820 | 1000kg |

Product detail pictures:

Related Product Guide:

Being supported by an highly developed and skilled IT group, we could offer you technical support on pre-sales & after-sales support for Chinese wholesale Automatic Stitcher Machine - Carton Box Stapler Stitching Machine – Canghai , The product will supply to all over the world, such as: Roman, luzern, Florence, We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!