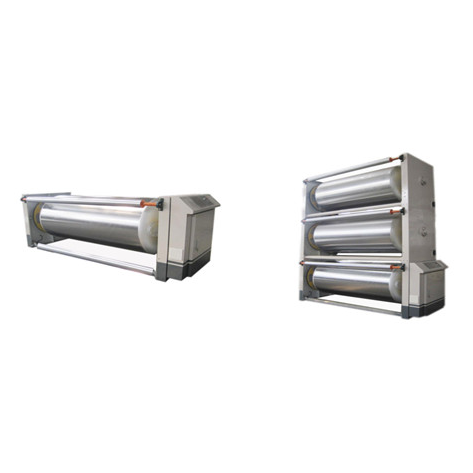

Chinese wholesale 5 Blade 8 Score Thin Blade Slitting Scorer - Computer Type Corrugated Carton Box Making Machine – Canghai

Chinese wholesale 5 Blade 8 Score Thin Blade Slitting Scorer - Computer Type Corrugated Carton Box Making Machine – Canghai Detail:

Function introduction

Man-machine interface—PLC control, this system is the robot operating system.

More humane, simple structure and easy to maintain.

1.Manual/auto feeder is available

2.Pre pressing roller,slitting blade and scorer holder are auto adjusted

3.Grinding knife is auto/manual

4.Cardboard thickness and press power are auto adjusted(Optional)

5.Jog for fine-adjusted

6.User-defined to set the distance of blades and scorers

7.Auto counter

8.Slitting and press line precision ±0.5mm

Automatic thin blade slitter and scorer machine function

◆Man-machine interface – PLC control, slitter thin knife row cutter single independent stepper motor control, automatic row order speed 1-20 seconds, error accuracy ± 0.5 mm.

◆The operation is very user-friendly, no technical content, and ordinary workers can operate.

◆Slitting: It adopts high-quality tungsten steel alloy blade, which has long service life, and the cut cardboard is neat without fracturing and burr.

◆Both sides of the thin blade are cut by rubber wheel pressing paperboard to overcome the phenomenon of no pressure line, separate board, deviation and straightness.

◆The sharpening device adopts both automatic and manual pneumatic grinding methods, which can work while grinding the knife to improve work efficiency.

◆The electrical appliances adopt domestic brands or imported products with reliable performance.

◆This machine can store 999 sets of orders, enabling non-stop change orders and manual change orders.

◆Equipped with an automatic paper feeder to adjust the size of the cardboard for one person operation, simple and quick。

◆The imported rubber wheel has a long service life.

◆Low noise, easy maintenance and high economic efficiency.

◆Better adapt to a variety of cardboard, and the paper is stable and accurate.

Main specification

|

N0 |

Model型号 |

ZBFY-JZ3250 |

ZBFY-JZ2750 |

|

1 |

No.s of slitting scoring

|

4 blades 6 lines |

|

|

2 |

Max.production speed

|

180m/min |

180m/min |

|

3 |

Max.feeding width

|

2750mm |

2250mm |

|

4 |

Max.slitting width

|

3100mm |

2600mm |

|

5 |

Min.slitting width

|

180mm |

180mm |

|

6 |

Min.feeding length

|

180mm |

180mm |

|

7 |

Min.scoring distance

|

40*135mm |

40*135mm |

|

8 |

Gap adjustment

|

Manual

|

Manual

|

|

9 |

Main motor power

|

5.5-6KW |

|

|

10 |

Dimension (W*L*H)

|

1570*3950*1500mm |

1570*3450*1500mm |

|

11 |

Overall weight

|

2880kg |

2780kg |

|

Components Configuration list |

|||

|

No. |

Name |

Brand name |

place of production; |

|

1 |

Touch screen |

Weiluntong |

Taiwan |

|

2 |

PLC |

Panasonic |

Japan |

|

3 |

circuit breaker |

intellectual circle |

Taiwan |

|

4 |

continuous |

Schneider |

France |

|

5 |

Button |

ABB |

Switzerland |

|

6 |

Main motor |

Guangzhou Jinlong Motor |

China |

|

7 |

Driver |

Research control |

China |

|

8 |

Driving motor |

Research control |

china |

|

9 |

reducer |

Yong Kun |

Taiwan |

|

10 |

Photoelectric sensor |

Omron |

Japan |

|

11 |

Proximity switch |

Omron |

Japan |

|

12 |

cylinder |

Yadeke |

Taiwan |

|

13 |

Frequency converter |

Mitsubishi |

Japan |

|

14 |

Bearing |

People – oriented Harbin |

China |

|

15 |

Tungsten steel blade |

260×158 8 hole |

God works in Chengdu |

|

16 |

Solenoid valve |

Sono Tiangong |

China |

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs of Chinese wholesale 5 Blade 8 Score Thin Blade Slitting Scorer - Computer Type Corrugated Carton Box Making Machine – Canghai , The product will supply to all over the world, such as: Doha, Swiss, Serbia, We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Let us work together to write a brilliant new chapter!

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!