2021 China New Design Corrugated Cardboard Production Line - Double Facer MachineDouble Baker – Canghai

2021 China New Design Corrugated Cardboard Production Line - Double Facer MachineDouble Baker – Canghai Detail:

Machine Description

*Corrugated paper enter into the double facer hot parts with heating and molding after pasted glue, and become board after cooling

Machine Function

*Hot Plates’ surfaces is ground and then chromed plated,width 600mm and 14pcs,cooling parts 4m

*Hot plates adopts the compressed press rollers structure,it lifting adopt pneumatic structure

*Heat conductive pipe of hot plates control the temperature segmented

*The inside of the hot plate is partition isolation structure,making the steam flow in S-shaped direction, and the separation function of steam and water is obvious,then improves the steam usage efficiency

*Up convey belt left and right correct by auto with both sides,Under belt adopt S type manual correct tension device

*Up belt adopt double cylinder S type tension device,down belt manual tension device(small amount adjust)

*Drive rollers’ surface is wrapped by rubber with middle height,to make sure the board output smoothly

*Main drive motor: Variable frequency motor, high force when low speed start, high speed adjusting range, steady to use,easy to mend

*The electrical components adopt international famous brands, working stably and reliable

Machine Technical Parameter

| Working Width |

1800mm |

| Steam Pressure |

0.8-1.3Mpa |

| Air Pressure |

0.6—0.9Mpa |

| Up Drive Roller |

Φ637mm |

| Down Drive Roller |

Φ637mm |

| Front Driven Belt Rroller |

Φ321mm |

| Back Shaping Driven Belt Roller |

Φ215mm |

| Belt Press Roller |

Φ70mm |

| Shaping Holder Roller |

Φ86mm |

|

Note: All the surfaces of the rollers are ground and then chromed plated |

|

Main Components Brand

| Components Name |

Brand |

| Main Frame | Tangshan |

| Cotton Belt |

Shenyang |

| Pneumatic system |

Zhejiang |

| Steam Trap | Henan |

| Main electrical |

Schneider |

| Button |

Schneider |

| Main motor |

Hebei |

| PLC |

Taiwan |

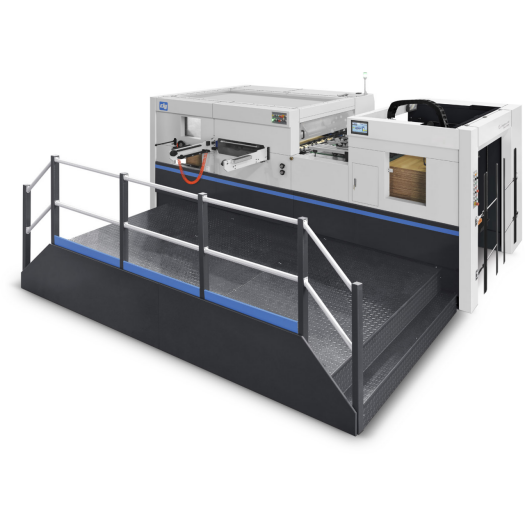

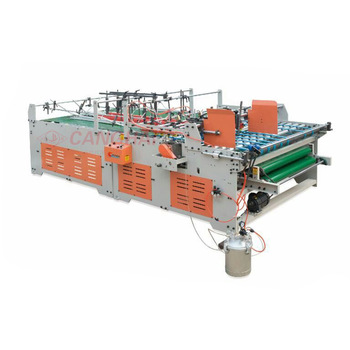

Product detail pictures:

Related Product Guide:

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for 2021 China New Design Corrugated Cardboard Production Line - Double Facer MachineDouble Baker – Canghai , The product will supply to all over the world, such as: Jamaica, Pakistan, London, We always insist on the management tenet of "Quality is first, Technology is basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.