100% Original Corrugated Cardboard Line - Thin Blade Slitter Scorer Machine – Canghai

100% Original Corrugated Cardboard Line - Thin Blade Slitter Scorer Machine – Canghai Detail:

►Structure and Features

1. Change order fast, 3-8 seconds for changing order, the two machines can be achieved with no slow down immediately for a single.

2. Automatic tracking production line speed to ensure its synchronization with on-line production management system, and compatibility.

3. By the high-quality imports of industrial computers and high-performance programmable controller configuration, lower computer control system.

4. Three kinds of pressure line forms: convex on concave (three lines), convex on the concave (five lines), convex on the flat, all three pressure lines can form an electric conversion. Creasing wheel depth by computer control, linear, easy to bend.

5. Using a thin tungsten steel alloy blade, blade sharp, long life of more than 8 million meters.

6. Brothers of computer control, automatic or manual knife sharpener, you can trim the edge of the Brothers, improve production efficiency.

7. Imported synchronous drive unit, semi-precision, long life, low noise operation.

►Technical parameter

► Motor

1, Max. width:2000mm

2, specification: 5 knives 8 lines

3, Min. Cut width:135mm

4, Max cut width:2050mm

5, Min pressure line:0mm

6, cutter wheel positioning accuracy: ±0.5mm

1, Knife motor:0.4KW

2, Knife driver motor:5.5KW

3, ine driver motor:5.5KW

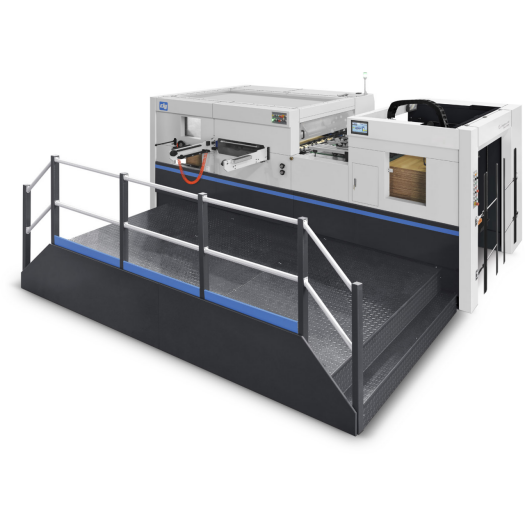

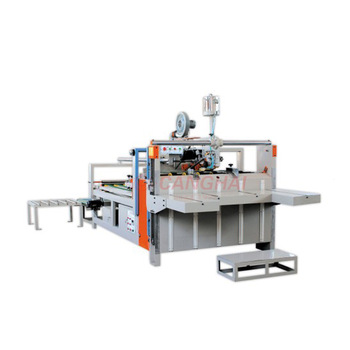

Product detail pictures:

Related Product Guide:

Our business promises all users of the first-class items and the most satisfying post-sale company. We warmly welcome our regular and new prospects to join us for 100% Original Corrugated Cardboard Line - Thin Blade Slitter Scorer Machine – Canghai , The product will supply to all over the world, such as: Marseille, South Korea, Saudi Arabia, Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.